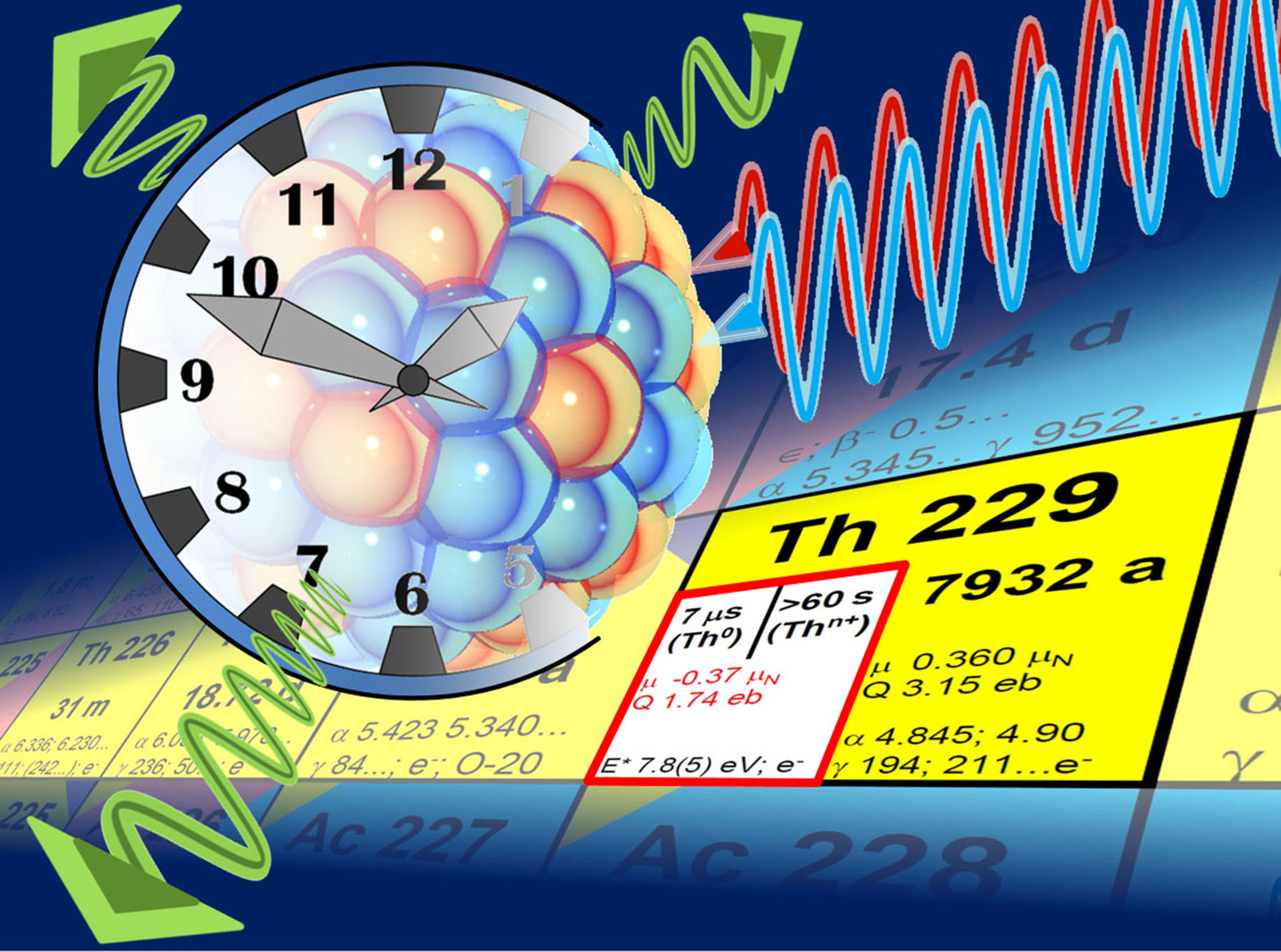

Thorium Nuclear Clock – the world's most accurate clock

The development of the world's most precise clock is the ambitious goal of the “Thorium Nuclear Clock” project, in which Fraunhofer-CAPS scientist Dr. Johannes Weitenberg is involved. Conventional atomic clocks on the effect of the characteristic frequency of radiation transitions in the electron shell. The Thorium Nuclear Clock, on the other hand, uses effects in the atomic nucleus.

The research project was selected by the European Research Council (ERC) for an ERC Synergy Grant and is financed with 13.8 million euros for a project duration of six years.

Prof. Thorsten Schumm from the Atominstitut at the TU Wien, Austria, will lead the project and work together with Ekkehard Peik (Physikalisch-Technische Bundesanstalt, Braunschweig, Germany), Marianna Safronova (University of Delaware, USA) and Peter Thirolf (Ludwig-Maximilians-Universität München, Munich, Germany). Further team members are Adriana Pàlffy-Buß (Max Planck Institute for Nuclear Physics, Heidelberg, Germany) and Johannes Weitenberg (Fraunhofer Cluster of Excellence Advanced Photon Sources CAPS, Aachen, Germany).

Fraunhofer Cluster of Excellence

Fraunhofer Cluster of Excellence