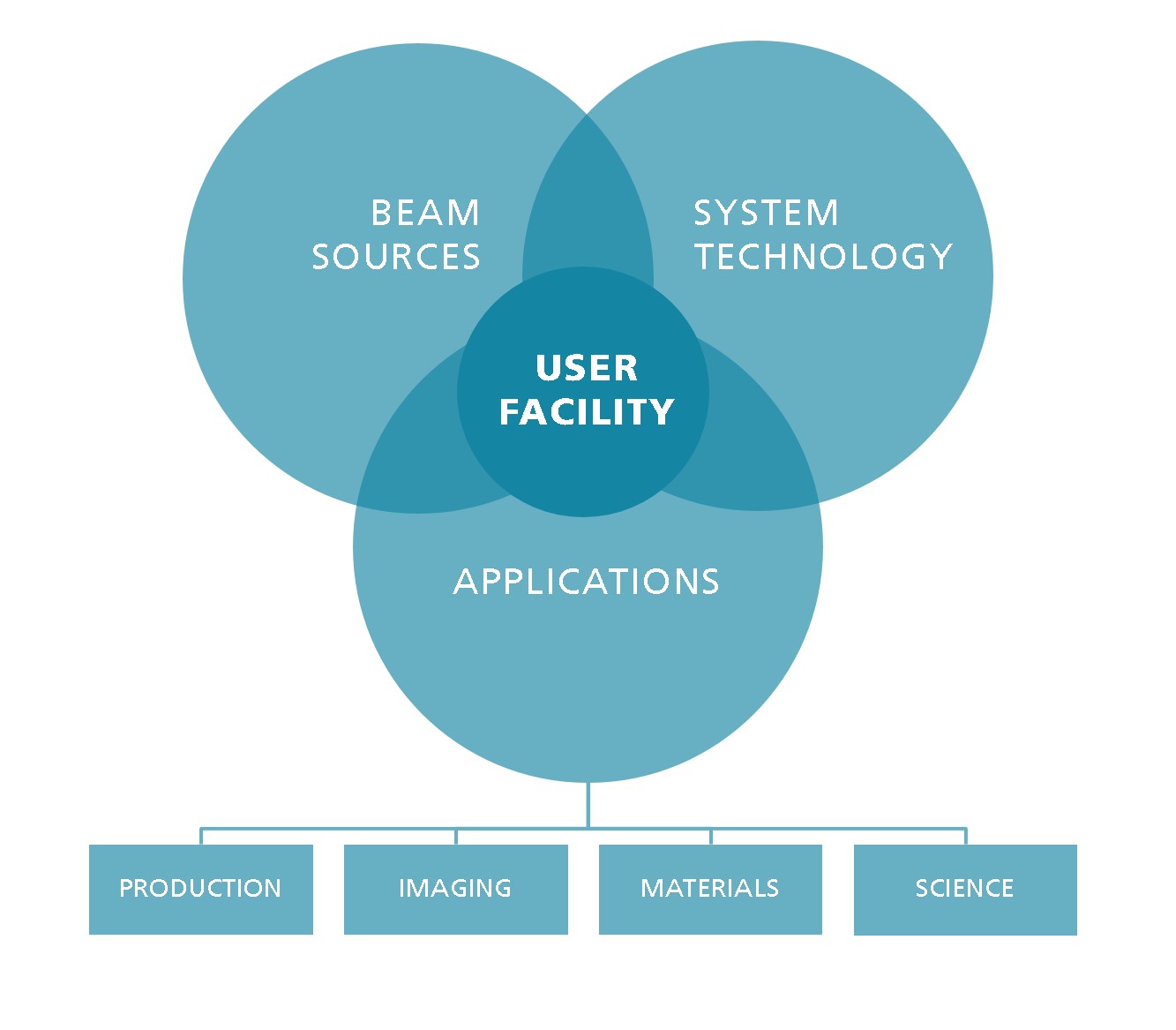

In the Fraunhofer Cluster of Excellence Advanced Photon Sources CAPS, experts from 13 different Fraunhofer Institutes are working together to develop new multi-kW ultrafast lasers, thereby opening up a whole range of new application fields. To accomplish this, application labs are being created in Aachen and Jena, where the Fraunhofer experts can work alongside partners from industry and research with the new beam sources and the associated system technology.

Brochure

Expertise thanks to combined know-how

Ultrafast lasers are unique: Their extremely high peak power allows them to process virtually all materials, while they are also extremely precise and minimize heat input into the material. Already today, they are used for operating on eyes or for cutting smartphone display glass. So far, however, the technology has been limited by the low average power of the lasers.

In order to change this, the Fraunhofer-Gesellschaft launched the Fraunhofer Cluster of Excellence Advanced Photon Sources CAPS in 2018. Its goal is to develop various multi-kW ultrafast laser systems. The project partners are developing both the appropriate system technology and a large number of new applications.

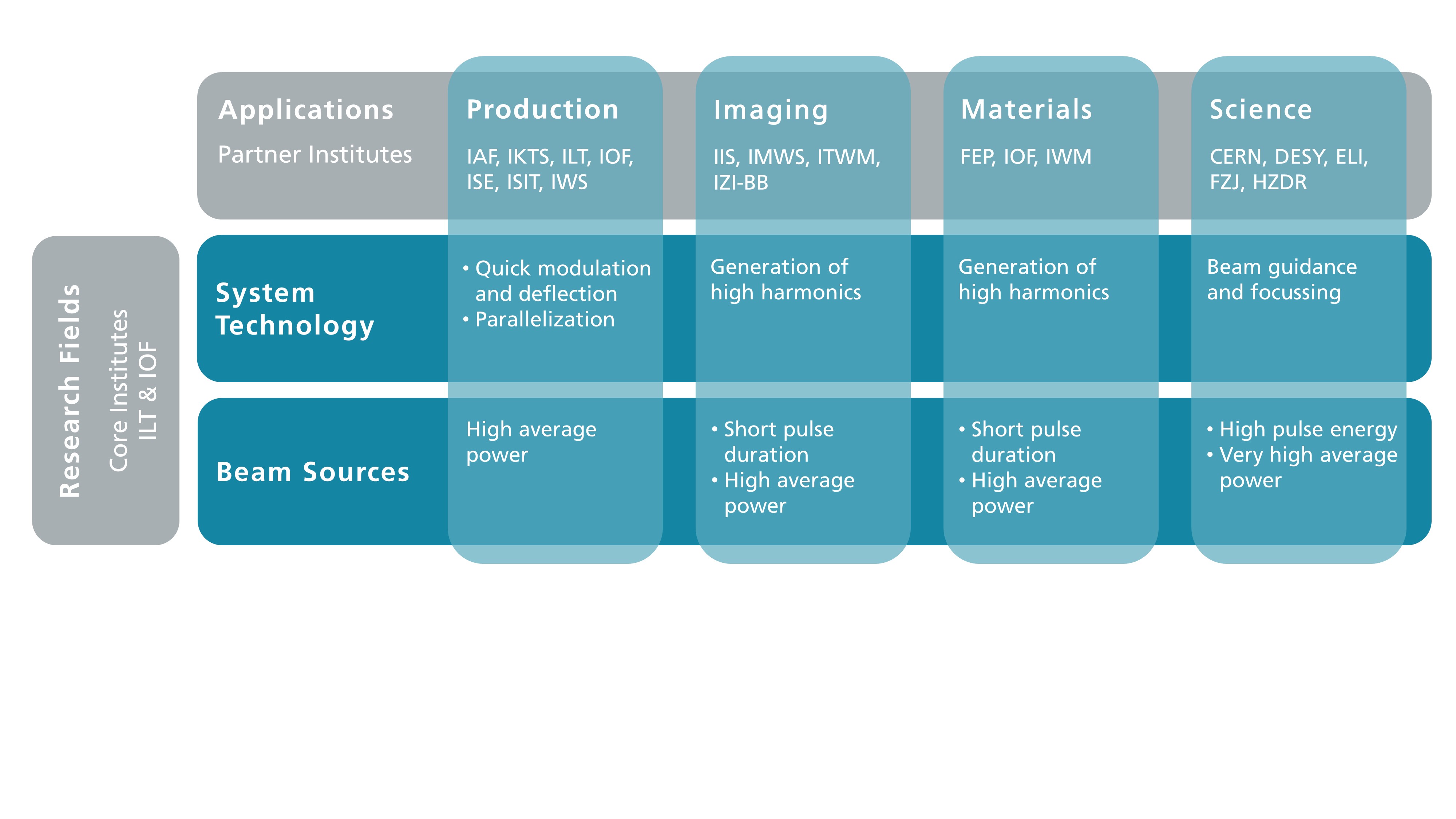

Currently, 13 Fraunhofer Institutes are involved, with the Fraunhofer Institute for Laser Technology ILT in Aachen and the Fraunhofer Institute for Applied Optics and Precision Engineering IOF in Jena coordinating the cluster. The two institutes are international leaders with complementary technical approaches for the development of high-power beam sources for ultrashort laser pulses.

Fraunhofer ILT – multi-kW lasers with 100 GW pulse power

INNOSLAB technology was developed at Fraunhofer ILT, a technology in which the pulses are amplified in slab-shaped laser crystals. The project partners aim to reach an output power of up to 2 kW from a single laser crystal; with several of these amplifier stages, the power should be scaled to 5 kW. In a thin-disk power amplifier, this output power will finally be doubled to 10 kW.

Fraunhofer IOF – new ultrafast systems exceeding 10 kW power

The Jena laser researchers specialize in the coherent combination of fiber lasers. For such lasers, they hold the current world record: 3.5 kW of ultrafast radiation from four coherently combined fiber channels. For 2019, it is planned to scale the system up to 10 kW and to 20 kW for the intermediate.

Performance data of the ultrafast beam sources

The pulse duration of the ultrafast laser of the Cluster of Excellence CAPS can be set from ns and ps down to about 50 fs based on the application. The partners also plan to generate very short pulses well below 50 fs, pulse energies above 5 mJ and pulse sequences with very high repetition rates and average powers in the multi-kW range. In addition, the teams also want to generate intense ultrafast radiation in other spectral ranges from EUV to THz.

The virtual institute

The Fraunhofer Cluster of Excellence Advanced Photon Sources CAPS is one of six current research clusters of the Fraunhofer-Gesellschaft. In these, the Gesellschaft is enabling its institutes to collaborate on developing and processing systemically relevant topics through an inter-institute research structure. For external partners they each act as a ”virtual institute” that can be spread over several locations and can draw on common know-how and IP pool. Not only have they placed the temporary implementation of individual projects in the foreground, but they are also creating a roadmap to develop complex technology trends for the long-term.

Partner insitutes

- Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP, Dresden

- Fraunhofer Institute for Applied Solid State Physics IAF, Freiburg im Breisgau

- Fraunhofer Institute for Integrated Circuits IIS, Erlangen

- Fraunhofer Institute for Ceramic Technologies and Systems IKTS, Dresden

- Fraunhofer Institute for Laser Technology ILT, Aachen

- Fraunhofer Institute for Microstructure of Materials and Systems IMWS, Halle (Saale)

- Fraunhofer Institute for Applied Optics and Precision Engineering IOF, Jena

- Fraunhofer Institute for Solar Energy Systems ISE, Freiburg im Breisgau

- Fraunhofer Institute for Silicon Technology ISIT, Itzehoe

- Fraunhofer Institute for Industrial Mathematics ITWM, Kaiserslautern

- Fraunhofer Institute for Mechanics of Materials IWM, Freiburg im Breisgau

- Fraunhofer Institute for Material and Beam Technology IWS, Dresden

- Fraunhofer Institute for Cell Therapy and Immunology IZI-BB, Leipzig

More power enables more throughput

Now that the power of ultrafast lasers can be scaled to a level an order of magnitude greater than other systems available today, a system’s throughput can be significantly increased when ultrafast lasers are used. This makes them interesting for many new machining processes and can open up systemically relevant markets. The advantages of the ultrafast lasers come into play as versatile precision tools – especially for applications that need extremely high power densities.

Independent of the material

Relevant interaction processes of ultrashort laser pulses with materials are largely independent of the material. For example, the same laser can be used to process standard materials such as metals (steel, copper), semiconductors (silicon, GaAs, SiC) and dielectrics (glass, sapphire) as well as composite materials such as GFRP or CFRP. Even biological materials can be precisely ablated or cut with ultrafast lasers.

High precision

Ultrashort pulses can reach a precision of less than 100 nm during ablation. Even today, this precision is used, for example, in eye surgery. However, with the new ultrafast lasers and the corresponding process technology, this precision is now available at high throughput. Thus, multi-beam optics from a single high-power laser beam can be used to produce a variety of partial beams, all of which drill in parallel with micrometer precision.

The ultrafast radiation can be modulated very precisely with different methods, making it possible to process in a component’s volume. In the beam focus, material properties are changed selectively without creating cracks or cavities.

Independent of the tool

Like all lasers, the new ultrafast systems work in a non-contact and wear-resistant manner. Many beam properties can be controlled. Especially in a digitized production process, the systems require almost no lead time.

Ultrafast laser opens up new markets

Scaling to kW power opens up completely new markets for ultrafast lasers. In addition to classic materials processing, where they can cut and drill ultra-hard materials with the utmost precision, they are also becoming interesting for largescale applications in photovoltaics and battery manufacturing.

Ultrafast lasers can make significant progress in many areas of metrology, for example, as coherent EUV sources in lithography and in imaging processes for materials research, biology and medicine.

Whole new possibilities will also arise when prospective ultrafast lasers are able to accelerate electrons or protons. They could revolutionize both molecular imaging and radiotherapy.

Application laboratories in Aachen and Jena

A major goal of the project is the early work on various applications. For this purpose, the coordinating Fraunhofer institutes – IOF and ILT – will already be making two application laboratories available in Jena and Aachen with several kW ultrafast laser sources as early as 2019.

In addition to the beam sources, the application laboratories are also equipped with the necessary process technology. This guarantees that the various users can work professionally on these application laboratories from day one.

The laboratory at Fraunhofer ILT will be located next to the actual laser development laboratory and will offer a separate beam source. This allows experiments to be carried out in three different chambers in parallel. The opening at the end of 2019 will feature a source that has 500 watts, pulse energies up to 1 mJ and pulse durations below 100 fs, and will be scaled to 2.5 kW (5 mJ) by mid-2020. The metrology equipment includes an extensive range of beam diagnostic tools.

At the Fraunhofer IOF, two laser systems are planned for the launch. Users have ultrashort laser pulses emitting at a wavelength of 1 μm and < 200 fs duration, with up to 1 kW average power and pulse energies up to 2 mJ. A subsequent pulse compression unit enables efficient pulse shortening below 30 fs. At 2 μm wavelength, the laser source will have average powers of 100 W and pulse energies of 0.2 mJ. In addition, there is a setup for the generation of coherent EUV radiation in the spectral range of 20 to 90 eV (60–13 nm) as well as a comprehensive EUV measurement technology including a camera. A vacuum chamber is also available for the EUV experiments. The lab will be operational by the end of 2019.

Wide range of applications

From the very beginning the application laboratories will be organized as user facilities. In addition to the partner institutes of the Fraunhofer-Gesellschaft, the research cluster CAPS is already cooperating with several companies and internationally renowned research institutions. Together they will work on projects in the future fields of production, imaging and materials as well as in basic research.

In the application laboratories, high-power beam sources will be set up and put into operation from 2019 onwards. The parameters of the beam sources will be tailored to meet the individual needs of the users.

System technology and components

In addition to developing various laser sources (Fraunhofer ILT and IOF), the entire project has placed great emphasis on setting up suitable system technology. Alongside purely optical high-performance components, this includes, for example, the development of new scanner systems. Fraunhofer ISIT will transfer the advantages of the silicon-based MEMS scanner technology to high laser power; Fraunhofer IWS will combine these with classic high-performance scanner technology. In a further step, Fraunhofer IWS will use its Direct Laser Interference Patterning technology (DLIP) with ultrashort pulses for the first time.

Production

Applications of ultrafast lasers in production make processes possible that are superior to classical processes in terms of precision, selectivity, flexibility and/or they can reduce the number of process steps. But they also have to be economical. A correspondingly high throughput requires not only ultrafast lasers with a high average power, sometimes well in excess of 1 kW, but also system technology for high-rate structuring so that this power can be implemented without causing thermal damage.

There are already a number of project ideas for the application of the multi-kW ultrafast lasers. This includes the texturing of silicon wafers for the solar industry (Fraunhofer ISE and IWS). The corresponding process requires power in the multi-kW range to establish further laser-based processes and further cost reductions in production of solar cells. Also for the production of lithium batteries, ultrafast lasers could increase their efficiency (Fraunhofer IKTS, IWS and ILT). There are also great opportunities with the machining of highly wear-resistant ultra-hard ceramics materials (Fraunhofer IKTS, IWS and ILT).

New applications in imaging and materials research use secondary radiation that can be generated with ultrafast lasers. For this reason, the intensive laser pulses can be used e.g. to generate coherent, very short-wave radiation down to the spectral range of soft X-rays.

Imaging

A key challenge faced by biomedical applications and material analytics is imaging technologies for detecting extremely small objects, such as single cells or molecules. A three-dimensional volume image can be reconstructed with a correspondingly large number of radiographic images.

Of particular interest is tomography based on coherent diffraction imaging (CDI) data at a wavelength of 13.5 nm. A variable EUV radiation wavelength makes additional spectral analysis possible and thus the vision of ”4D-nanoCT”, a process for four-dimensional X-ray imaging.

Achieving short exposure times with coherent EUV light sources requires efficient ultrashort pulse lasers with more than 10 kW average power and pulse durations below 50 fs as a driver. Such lasers provide unique perspectives; for example, thanks to the extremely short wavelength, extremely high resolutions can be achieved (Fraunhofer IZI-BB).

Even shorter wavelengths for the exploration of materials are achieved with so-called Compton sources. These are based on an interaction of pulsed laser beams with conventionally generated electron beams (Fraunhofer FEP and IIS).

The various partners will contribute their expertise in biology and medicine (Fraunhofer IIS), semiconductor technologies (Fraunhofer IMWS) or data analysis and quality control (Fraunhofer ITWM).

Materials

USP lasers with average powers in the range of 10 to 20 kW open up completely new possibilities in the production of artificial materials and the investigation of new material conditions (non-equilibrium processes). Possibilities also arise here for quantum technologies, where N-type vacancies in diamonds can be activated for new quantum sensors (Fraunhofer IAF). Completely new options arise for the investigation of materials with laser-induced and therefore ultrafast electron beam sources (Fraunhofer FEP).

Technology transfer

A central goal of the research cluster is the transfer of the results into commercial implementation. This concerns the results of beam source and system technology development as well as those of application development. Industrial partners can use the laboratories of the User Facility to investigate possible application. In doing so, they can call on the knowhow of the various Fraunhofer institutes.

Fundamental research

The prospects are almost revolutionary for the development of laser-driven frequency conversion to spectral ranges that are inaccessible to the lasers themselves (e.g. soft X-rays or THz). Here, the CAPS institutes cooperate closely with several other research institutes in order to optimize the beam sources for use in research and industry. They aim to provide the power spectrum of synchrotron systems on an optical table.

The cluster team is working on the development of novel laser particle accelerators together with research institutions such as DESY in Hamburg, Helmholtz-Zentrum Dresden-Rossendorf and Forschungszentrum Jülich as well as international institutions such as CERN in Geneva and the European Light Infrastructure (ELI). The construction of such accelerators requires ultrafast lasers with average powers in the order of 100 kW. The facilities in the Fraunhofer Cluster of Excellence Advanced Photon Sources CAPS currently come closest to this and will break new ground for future technological developments.

Fraunhofer Cluster of Excellence

Fraunhofer Cluster of Excellence